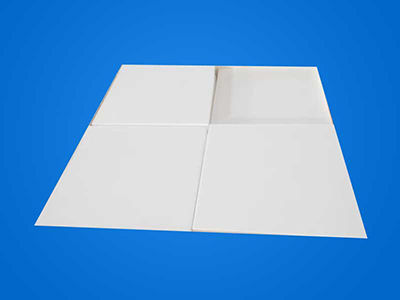

The three main factors that affect the quality of the Molding Plate are: raw materials, mold equipment and processing molding process.

First, raw materials are the core

The core of the raw material is molecular weight. In theory, the higher the molecular weight of the raw material, the better the abrasion resistance. However, as a wear-resistant sheet, other mechanical properties should also be considered, and its long-term use stability should be considered. Therefore, depending on the mold equipment and processing molding process, high molecular weight raw materials may not produce ultra high molecular weight polyethylene sheets with good comprehensive properties. At present, the processing technology of ultra-high molecular weight polyethylene sheets has not been standardized, and manufacturers vary widely. Mainly in mold structure and process control. Therefore, no difference was seen on the surface of the obtained ultra-high molecular polyethylene sheet, but the refractive index gap was very large. Here too, empirical things occupy a relatively large proportion.

Second, the mold

The production mold is the key factor that affects the quality of the compression plate, because: ① If the compression ratio design of the mold is not reasonable, it will cause the pipe to be difficult to squeeze out, or the compactness, insufficient pressure resistance, and low mechanical properties. ② The flow channel is not smooth, the raw materials are excessively degraded during the extrusion process, and the performance of the ultra-high molecular weight polyethylene pipe is reduced. ③ The structure is not reasonable, the plasticization is not good, or the fusion is not good, and the pipe is easy to crack. ④ The structure is unreasonable, the extrusion fluctuation is large, and the operation is difficult. The production of ultra-high molecular weight polyethylene sheets is mainly based on experience. The main reason is that the mold design is not reasonable. Good mold design will achieve the following effects. ① Good operation and stable production. As long as the temperature does not change significantly, the appearance of the pipeline will not be affected by changes in the external ambient temperature. ② The good internal indicators of the pipeline mainly refer to the compactness and degradation of ultra-high molecular weight polyethylene sheets.

Three, Extrusion process:

The extrusion process of the molded plate is also critical to the inherent properties of the pipe. Molded plates of different molecular weights require different processing and extrusion temperatures. When the molecular weight is 250 ± 500,000, the plasticizing temperature should be about 240 degrees. If it is too low, the surface of the tube will become stale and the plasticizing effect will be poor. For the same raw material, the mold should usually be adjusted to set the appropriate temperature.

Address: Zhaojiaqiao, Shebei Village, Xin'an Town, Deqing County, Zhejiang Province 313217, China

Phone: 0572-8080386

Fax: 0572-8083507

Email: info@nxptfesheet.com

Wechat:13665722632

SKYPE: hznx.ptfe

© Copyright 2015. Green Machine Tool Co., Ltd.